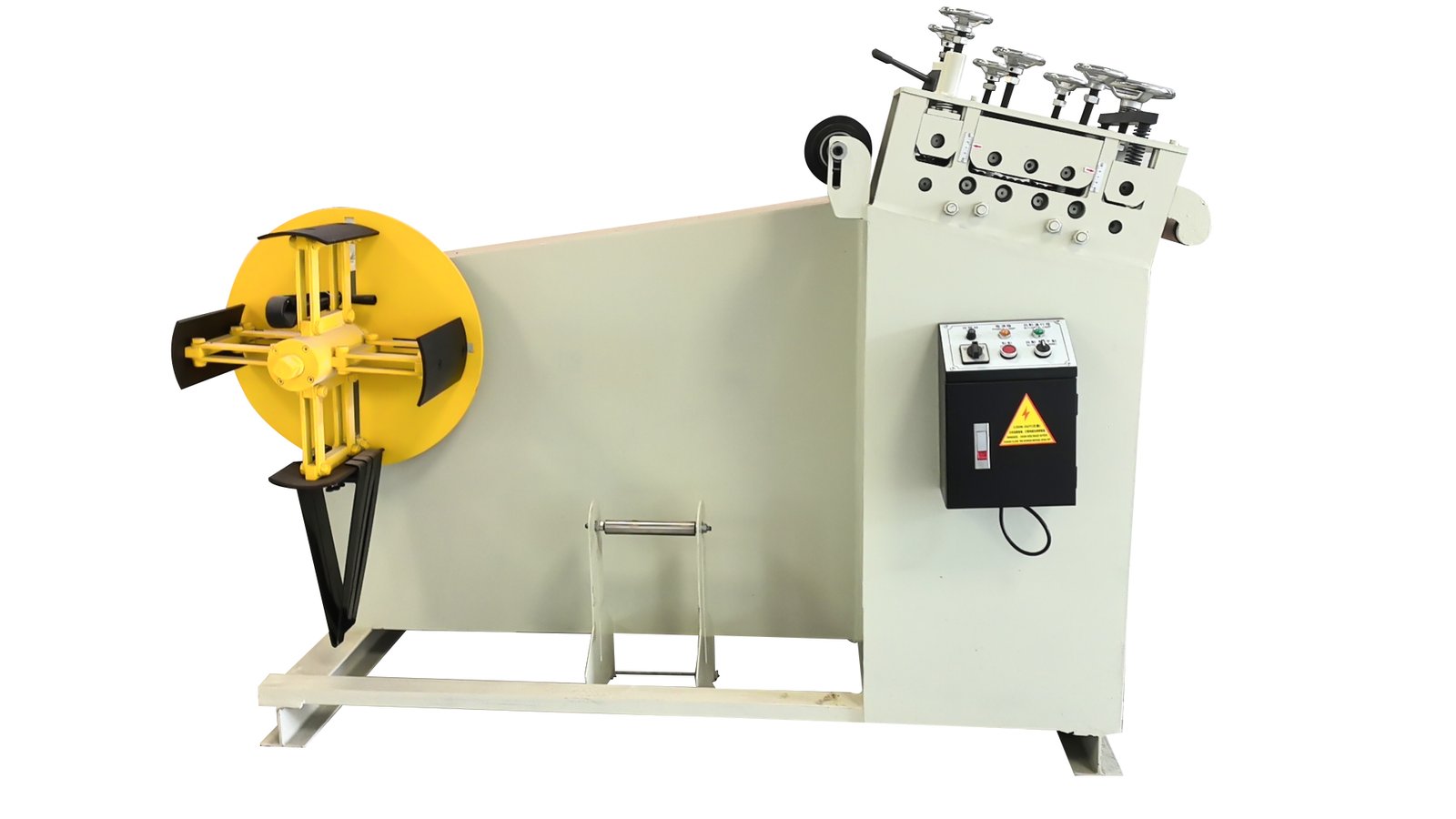

CNC 3-in-1 Feeder

Features

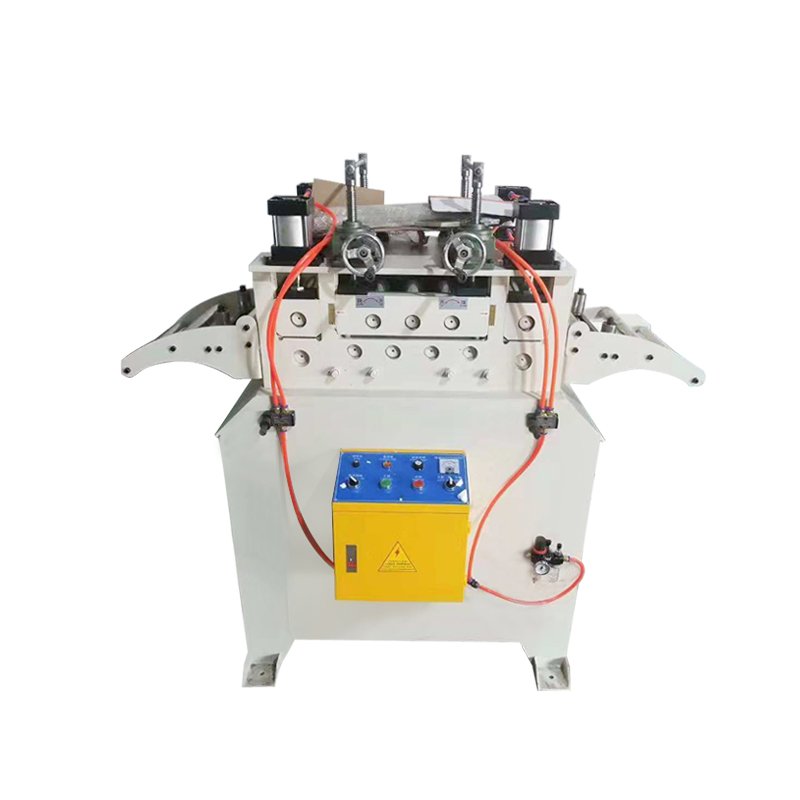

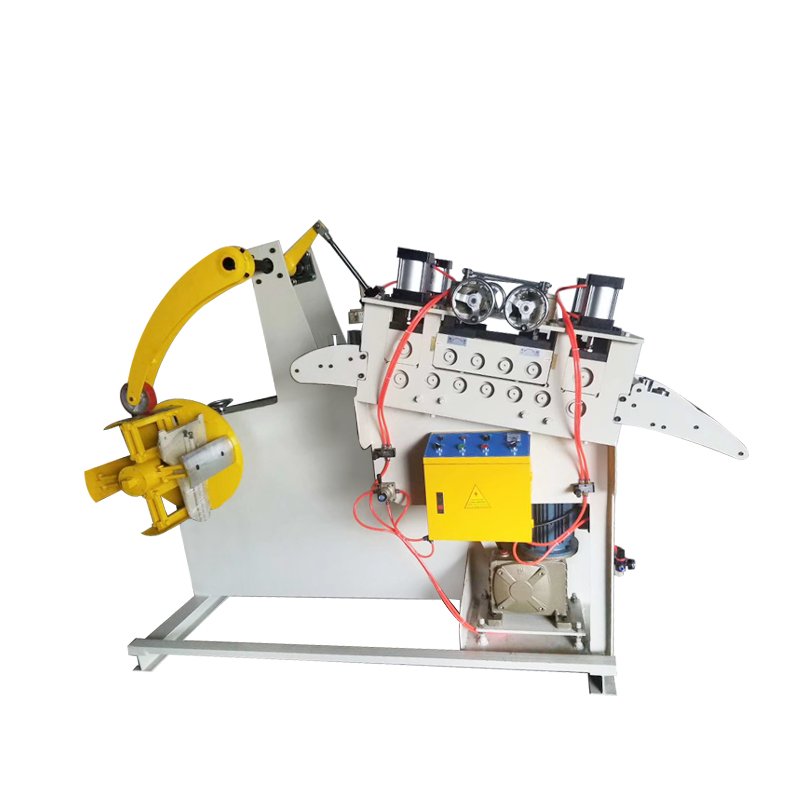

This equipment is a model specifically designed for the uncoiling and leveling functions of automated feeding of medium-to-thin plates in stamping processes. The gripping wheel rollers feature plow-blade sandblasted electroplated hard chrome surfacing, effectively increasing friction between the material and the rollers to prevent slippage during straightening and feeding, thereby achieving high feeding accuracy. The machine employs imported components, pneumatic elements, bearings, and electrical parts. The control system is equipped with a touch screen, offering large‑capacity memory for user product parameter information and a comprehensive equipment fault alarm system, ensuring longer machine service life, higher working efficiency, and more reliable safety performance.

Technical Specifications

-

Material type: Cold‑rolled sheet, carbon steel, galvanized sheet, stainless steel sheet

-

Material surface treatment: None

-

Material thickness: 3–3.2 mm (refer to the material leveling capacity table)

-

Material width: 80–800 mm

-

Yield strength: ≤ 245 N/mm²

-

Tensile strength: ≤ 392 N/mm²

-

Coil inner diameter: 450–530 mm

-

Coil outer diameter: 1400 mm

-

Coil weight: 5000 kg

Material type: Cold‑rolled sheet, carbon steel, galvanized sheet, stainless steel sheet

Material surface treatment: None

Material thickness: 3–3.2 mm (refer to the material leveling capacity table)

Material width: 80–800 mm

Yield strength: ≤ 245 N/mm²

Tensile strength: ≤ 392 N/mm²

Coil inner diameter: 450–530 mm

Coil outer diameter: 1400 mm

Coil weight: 5000 kg

Product Related Videos

- CNC 3-in-1 Feeder

.jpg)