I. Insufficient Air Pressure and Leakage

This is the most common cause. First, check whether the air compressor’s output pressure meets the equipment requirements (typically above 0.5 MPa). If the overall pressure is low, adjust the air compressor settings. Second, inspect the air circuit for leaks. Listen carefully for air leakage at tubing joints, speed control valves, and cylinder interfaces, and replace any damaged or aged tubing or sealing rings. In addition, malfunction or improper adjustment of the pressure-reducing valve can also directly lead to insufficient output pressure, and it should be readjusted or replaced.

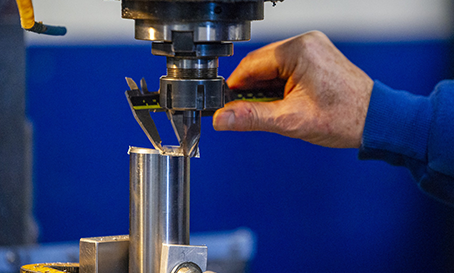

II. Cylinder and Material Clamping Mechanism Failures

As core actuating components, wear or aging of the sealing rings inside the cylinder can cause internal leakage, preventing air pressure from being effectively converted into clamping force. In this case, the cylinder needs to be disassembled by a professional and the seals replaced. At the same time, the clamping plate or clamping spring connected to the cylinder may be fatigued or broken, resulting in the failure to transmit sufficient pressure onto the material. Inspect and replace any damaged clamping components.

III. Mechanical Adjustment and Wear

Improper mechanical adjustments can also create the impression of insufficient pressure. For example, if the preload of the clamping spring is set too low, or the gap between the upper and lower feed rollers has increased due to wear, the material may not be clamped firmly. Refer to the equipment manual to readjust the preload and roller gap, ensuring they match the material thickness.